Prof. X.X. Xi(Temple University, USA) talked about “MgB2 thin films for SRF cavity applications”. Prof. Xi mentioned that clean MgB2 thin films have a low residual resistivity and high Tc of ~40K and are promising materials to RF cavity applications if we can obtain Hc1 values higher than that of Nb. He has been studying MgB2 thin films applying a hybrid-physical-chemical vapor deposition(HPCVD) method. He succeeded in obtaining high Hc1 of MgB2 film, higher than that of Nb by decreasing the film thickness. He also carried out the deposition of MgB2 film on Cu, which is important to cavity application. He observed the formation of Mg-Cu compound layer between Cu substrate and MgB2 film. He also observed the cracks introduced into the MgB2 films after the deposition. He mentioned that these cracks are due to the difference of thermal contraction between Cu and MgB2. He also carried out the coating of RF cavities with MgB2 and investigated the properties.

S.K. Chen(University Putra, Malaysia) reported on “Synthesis and optimization of superconducting properties of MgB2”. Dr. Chen fabricated MgB2 bulks by direct reaction between Mg and B or MgB4 and Mg. He mentioned that with increasing heat treatment temperature a compromise between grain connectivity and defect density becomes crucial in order to optimize Jc. He obtained a few orders of magnitude higher Jc values by the addition of SiC nano-particles. The field dependence of Jc was improved with a slight decrease of Tc by the SiC addition. He also mentioned that addition of excess Mg to MgB4(Mg1.5B2) increased the weight fraction of MgB2 together with unreacted Mg and enhanced Jc values.

P. Badica(National institute of Materials Physics, Romania) reported on “addition, co-additions and raw materials influence on MgB2 obtained by spark plasma sintering”. Dr. Badica mentioned that high density MgB2 bulks can be obtained by spark plasma sintering(SPS). He used MgB2 powder and additives or co-additives as a raw materials. He mentioned that the type of an additive is important, but the key element is not only that. The microstructure of SPS sample seems complicated. He also mentioned that the specific features of the raw powders (morphology, size, purity and so on) and processing conditions(e.g. interaction between co-additions or the mixing level of the powders) can or can’t lead to formation of pinning centers.

M. Muralidhar(Shibaura Institute of Technology, Japan) reported “low cost and high performance bulk MgB2 material for super-magnets”. Prof. Muralidhar fabricated MgB2 bulks by mixing crystalline boron and nano-meter-sized amorphous boron powders encapsulated in carbon to reduce the cost of the bulk materials. He obtained sharp superconducting transitions of with Tc,onset around 38.6-27.2K for the bulks prepared with the mixture of crystallince boron and carbon-coated amorphous boron. He mentioned that the highest Jc values of 470kA/cm2 and 310kA/cm2 in self-field and 1T, respectively, were obtained at 20K for the MgB2 sample with 1.5% of carbon in the carbon-encapsulated boron.

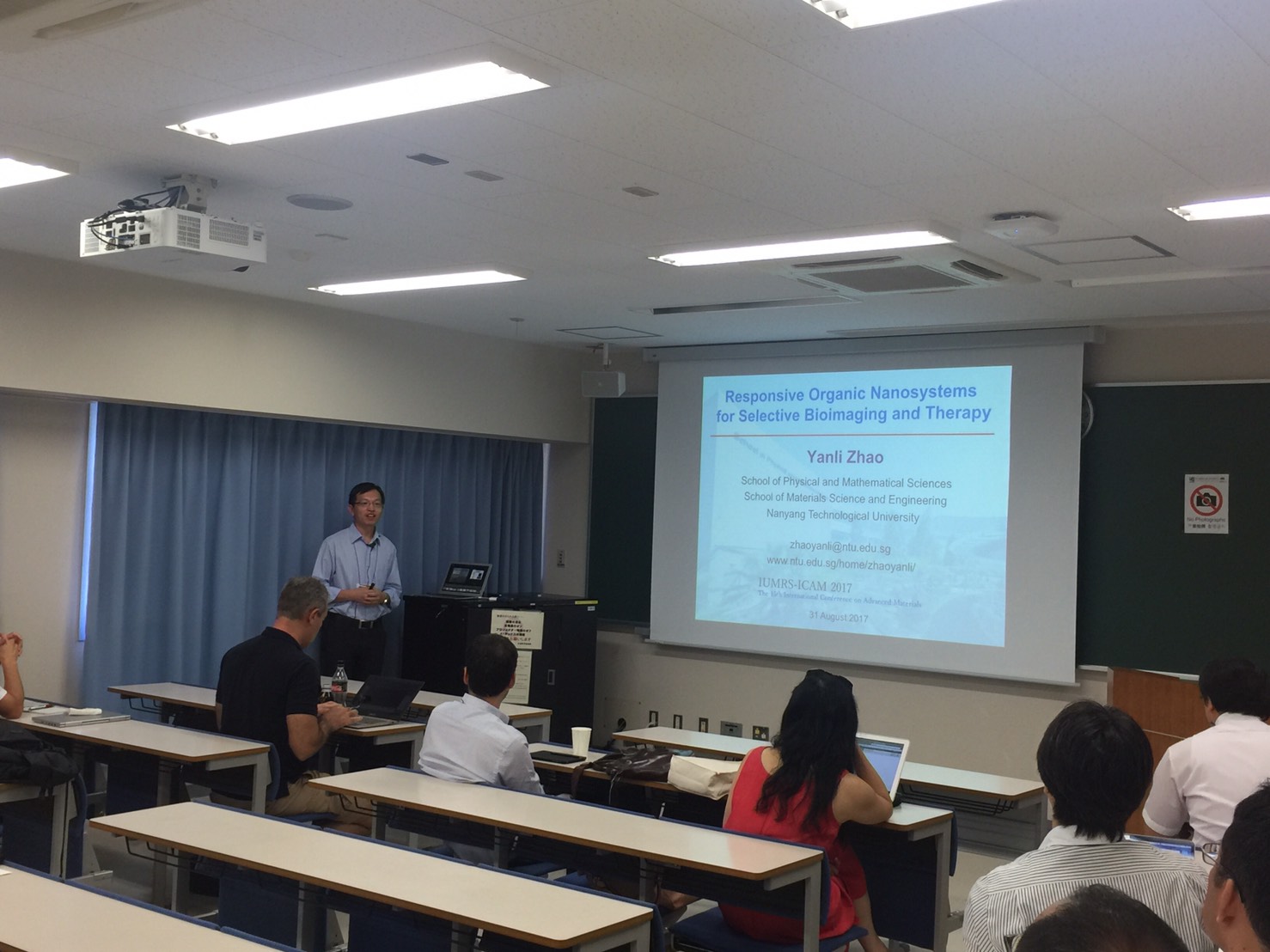

Keynote talk by prof. Zhao

Keynote talk by prof. Zhao